TEK7 Visualise the unseen. Design or optimise with confidence.

Computational Fluid Dynamics (CFD)

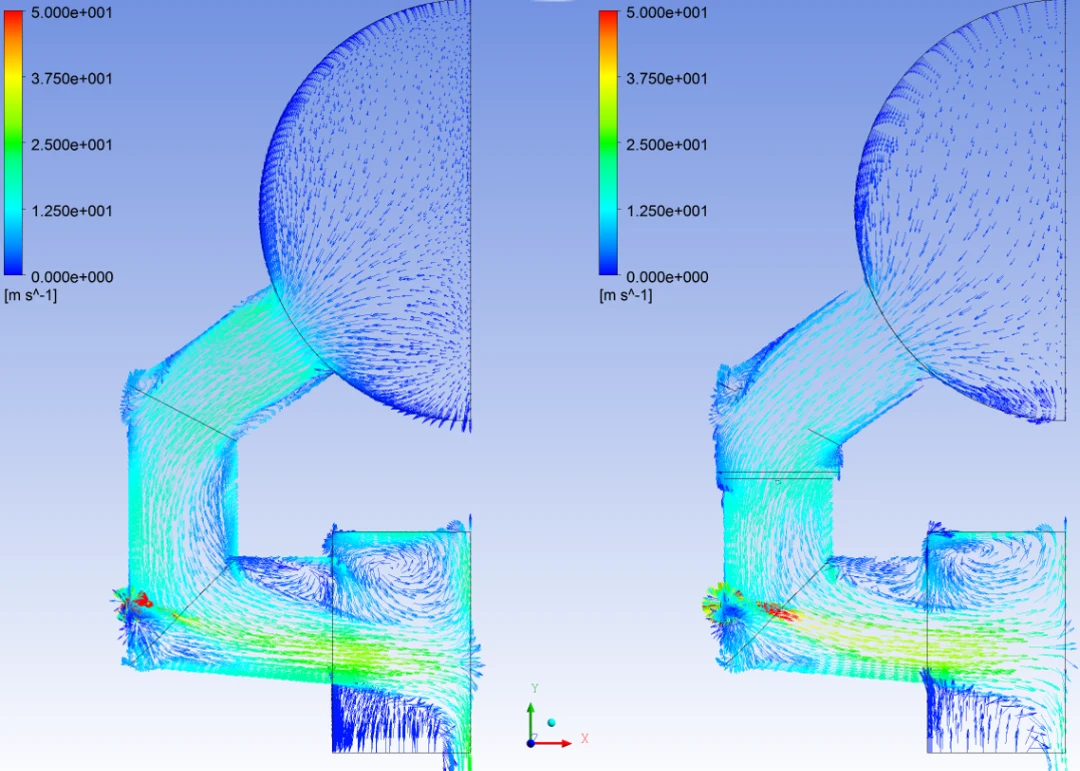

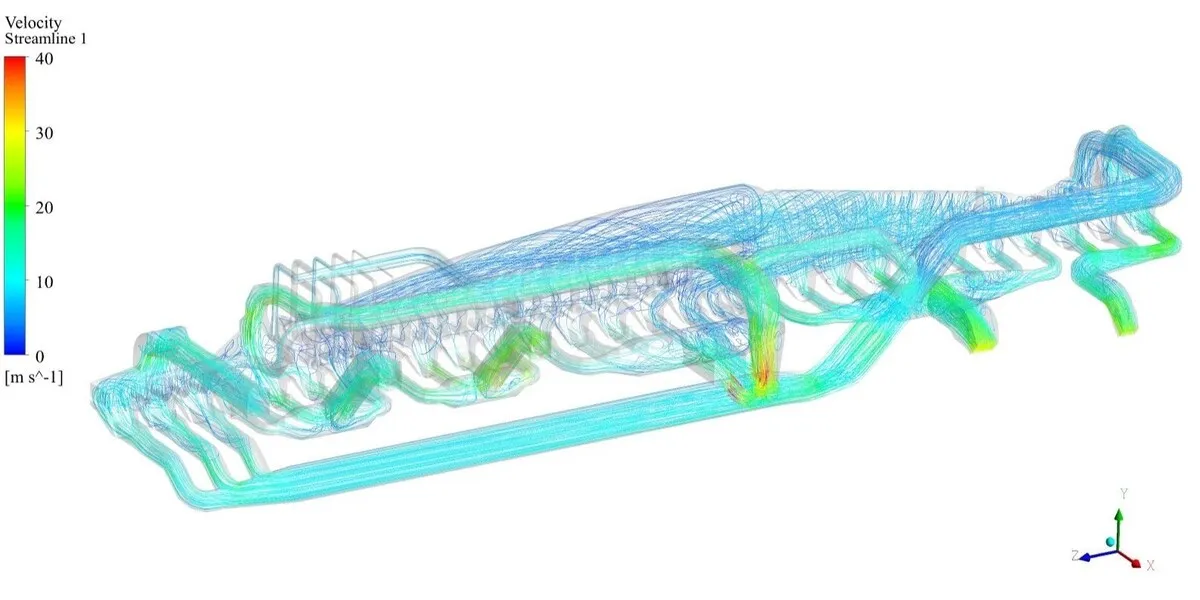

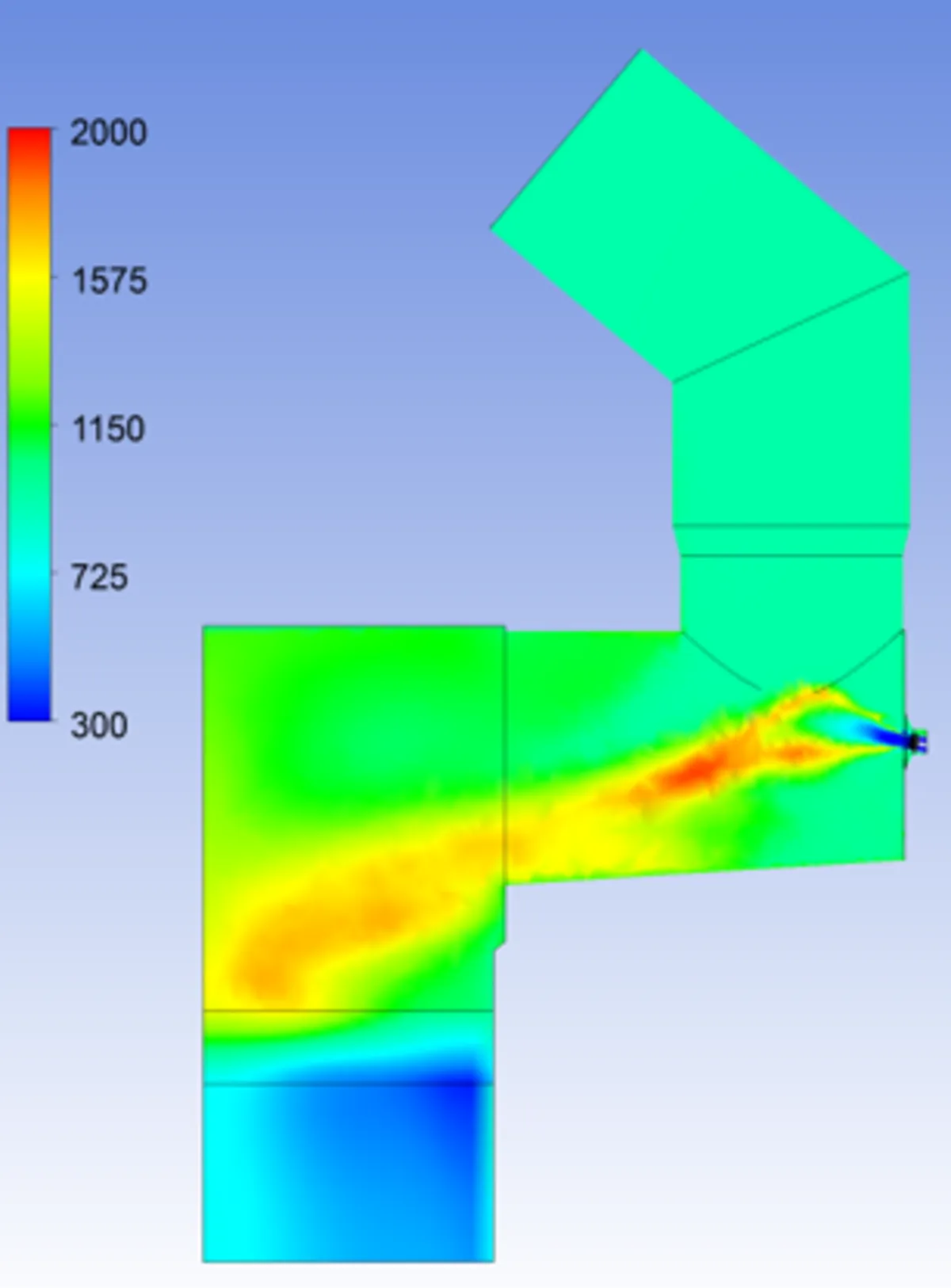

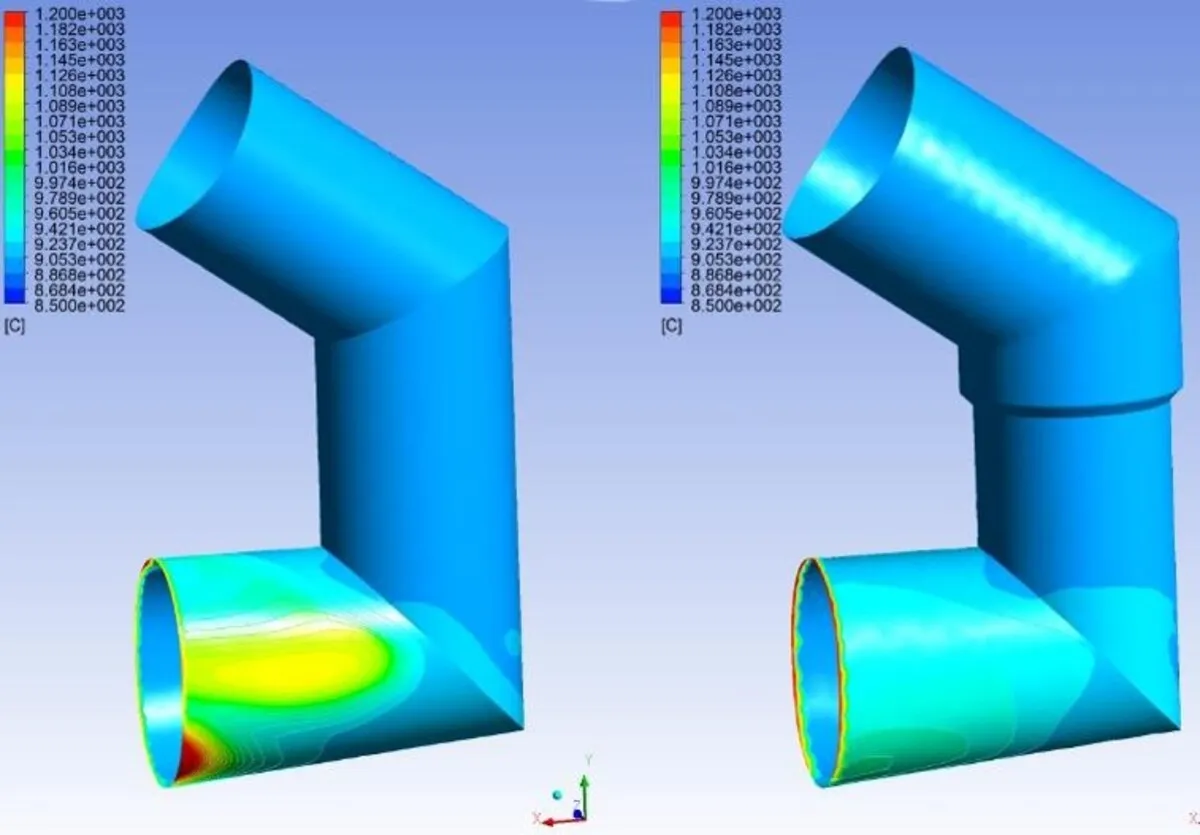

At TEK7, Computational Fluid Dynamics (CFD) is a key technology for designing, modernising, and optimising pelletising plants. The expert team uses CFD to simulate complex fluid, thermal, and mass transfer behaviours within the plant, turning operating data into clear, actionable insights. By accurately modelling airflow, heat transfer, and process interactions, uncertainty is reduced and data-driven decisions are supported to enhance performance, efficiency, and reliability.

— TEK7

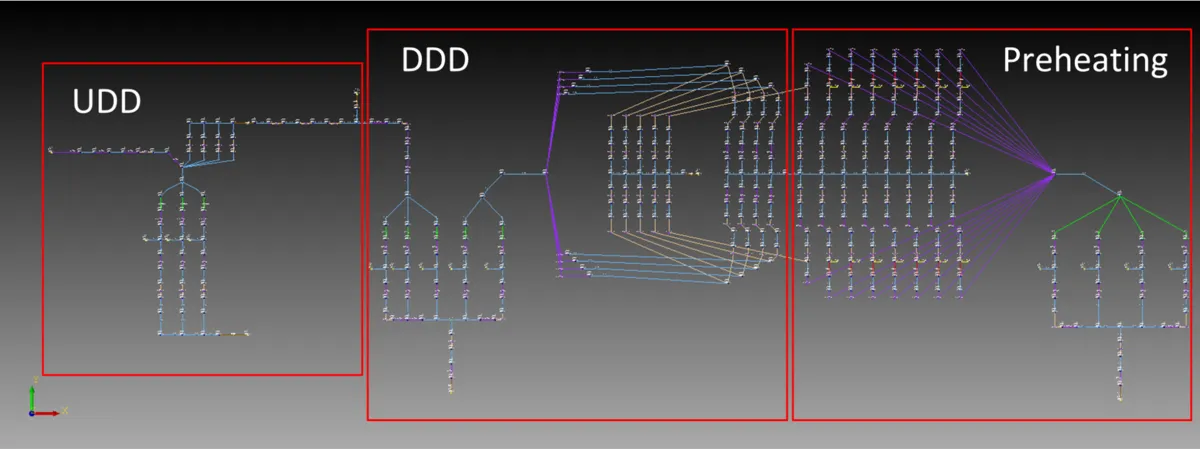

Using 1D, 2D, and 3D simulations, we can replicate real-world operating conditions in a virtual environment. This allows us to visualise and evaluate plant processes with precision, reducing uncertainty, minimising risk, and supporting informed, data-driven decisions throughout the project lifecycle.

CFD in Action: TEK7’s Advanced Application

TEK7’s CFD methodology begins with the development of a high-fidelity 3D model of the plant, including wet areas or void spaces that channel process gases from fans to exhaust stacks. For brownfield projects, simulations incorporate operational plant data and real boundary conditions, while for greenfield projects, they are based on design parameters and engineering assumptions to ensure precision and relevance.

This detailed CFD study allows us to:

- Diagnose root causes of performance limitations, such as airflow imbalances, localized overheating, or sub-optimal heat recovery.

- Evaluate the effectiveness of process fans and identify opportunities to improve pressure uniformity, airflow distribution, and energy efficiency.

- Optimise drying and induration processes by simulating pellet bed behaviour, temperature profiles, gas flow paths, and moisture removal rates across various operating scenarios.

- Model the interaction between combustion chambers, recuperation hoods, wind-boxes, and pellet beds, ensuring optimal thermal efficiency and uniform hardening of pellets.

By synchronising CFD results with operational data or design specifications and on-site measurements, assumptions are validated, model accuracy is improved, and targeted, implementable improvements can be proposed that align with the overall project strategy.

Strategic Benefits of CFD in Pelletising Plants

- Process Optimisation; Enables precise control over drying and induration conditions, leading to improved product quality and reduced energy usage.

- Design Validation; Provides assurance that proposed plant designs or upgrades will perform as intended before physical implementation.

- Troubleshooting Support; Helps identify and address elusive operational issues that cannot be easily observed through physical inspections alone.

- Long-Term Reliability; Supports predictive maintenance and improved asset lifecycle management.

CFD is more than a simulation tool; it is a strategic enabler. With TEK7’s deep domain expertise and advanced computational capabilities, pelletising operations can be modernised and optimised with greater confidence, unlocking enhanced performance, reliability, and efficiency.