TEK7 Building performance into every detail.

Engineering Design

At TEK7, we deliver comprehensive and integrated engineering design solutions that drive successful plant projects, whether building a new facility or optimising an existing plant. Our multidisciplinary team collaborates across process, mechanical, electrical, instrumentation, civil, and utility disciplines to create designs focused on safety, scalability, and long-term performance. By combining innovative thinking with rigorous analysis and practical experience, we produce future-proof solutions that optimise productivity, reliability, and sustainability.

— TEK7

Our engineering design philosophy ensures that every plant, system, or subsystem meets or exceeds performance expectations. By integrating assessment, innovative design, and advanced technology, TEK7 provides solutions that support operational excellence today and prepare your plant for future demands.

Process Engineering

- Process Assessment and Analysis; We begin by thoroughly assessing the pelletising process, whether in an existing plant or a new facility, to identify bottlenecks, inefficiencies, and opportunities for improvement. Key Performance Indicators (KPIs) such as production capacity, energy consumption, product quality, and compliance with safety and environmental regulations are carefully evaluated.

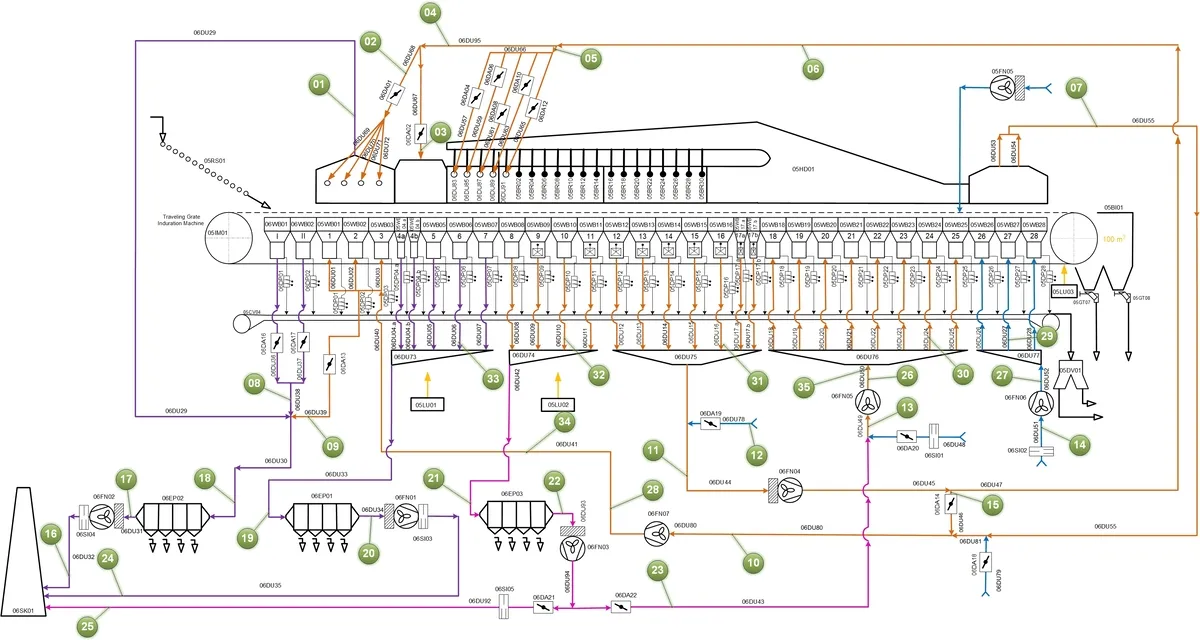

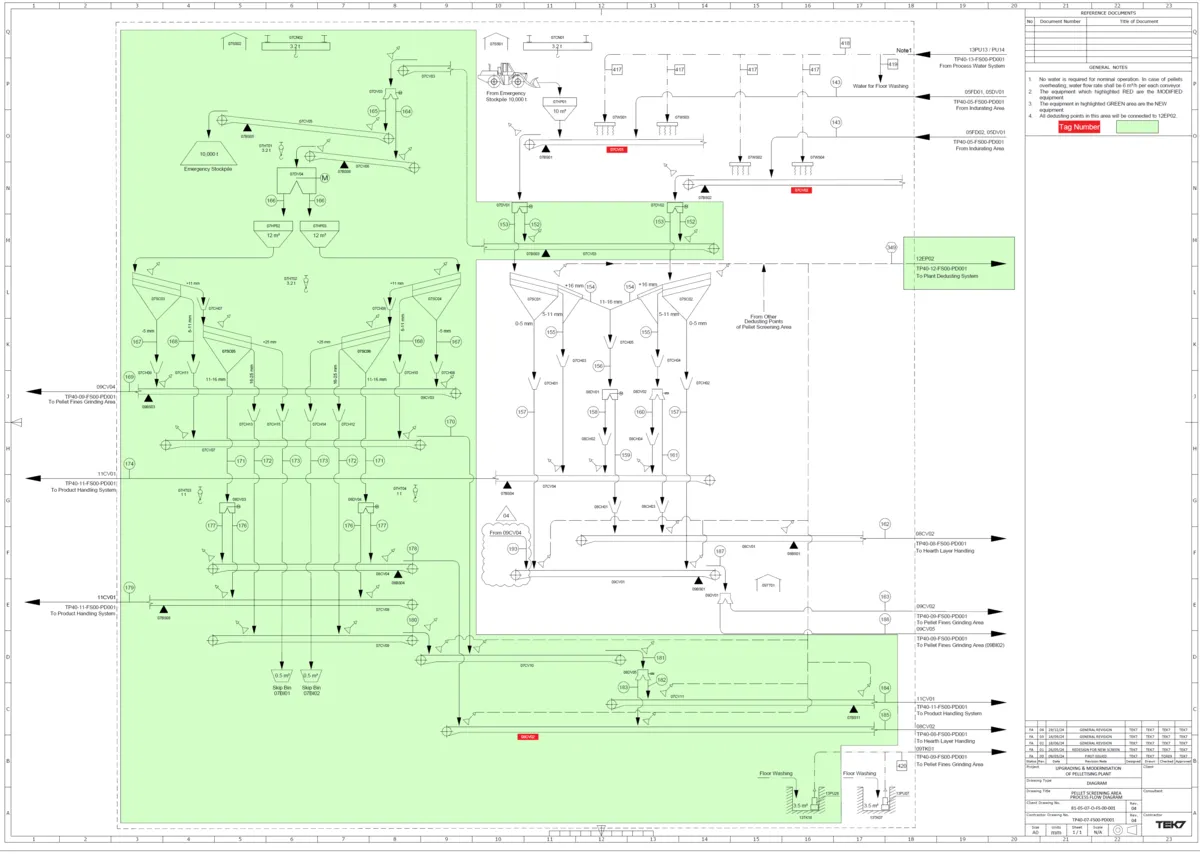

- Process Design and Optimisation; Our engineers develop optimised process flow diagrams (PFDs) and conduct detailed heat and material balances. Using advanced process simulations and modelling, we evaluate multiple scenarios to refine process parameters, improve productivity, and ensure consistent product quality while identifying opportunities for energy recovery and waste reduction.

- Equipment and Technology Selectionn; We design process systems to achieve high reliability, throughput, and maintainability. Our approach integrates advanced technologies and optimised configurations, ensuring operational efficiency, process stability, and environmental performance.

- Process Control and Automation; We design and implement control strategies to optimise plant operations and ensure consistent product quality. This includes integrating instrumentation, data acquisition, and automation systems to enhance process stability, responsiveness, and overall operational performance.

- Environmental Considerations; Our designs proactively address environmental impacts by proposing solutions to minimise emissions, water usage, and waste. We optimise dust control, noise reduction, and water treatment systems to ensure compliance with local regulations and promote sustainable operations.

Mechanical Engineering

- Equipment Assessment and Analysis; We conduct detailed evaluations of mechanical systems to understand performance characteristics, capacity, and operational constraints. This allows us to identify potential bottlenecks and reliability risks that could affect plant performance.

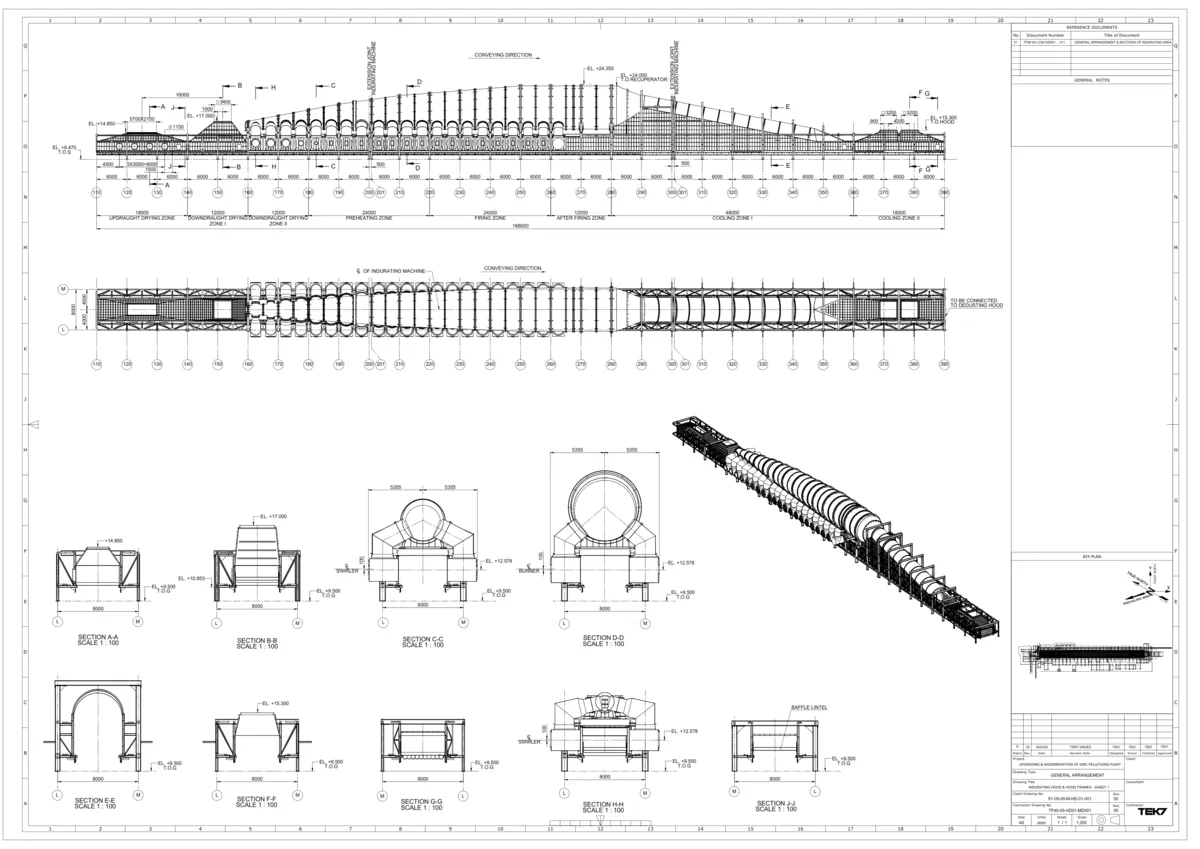

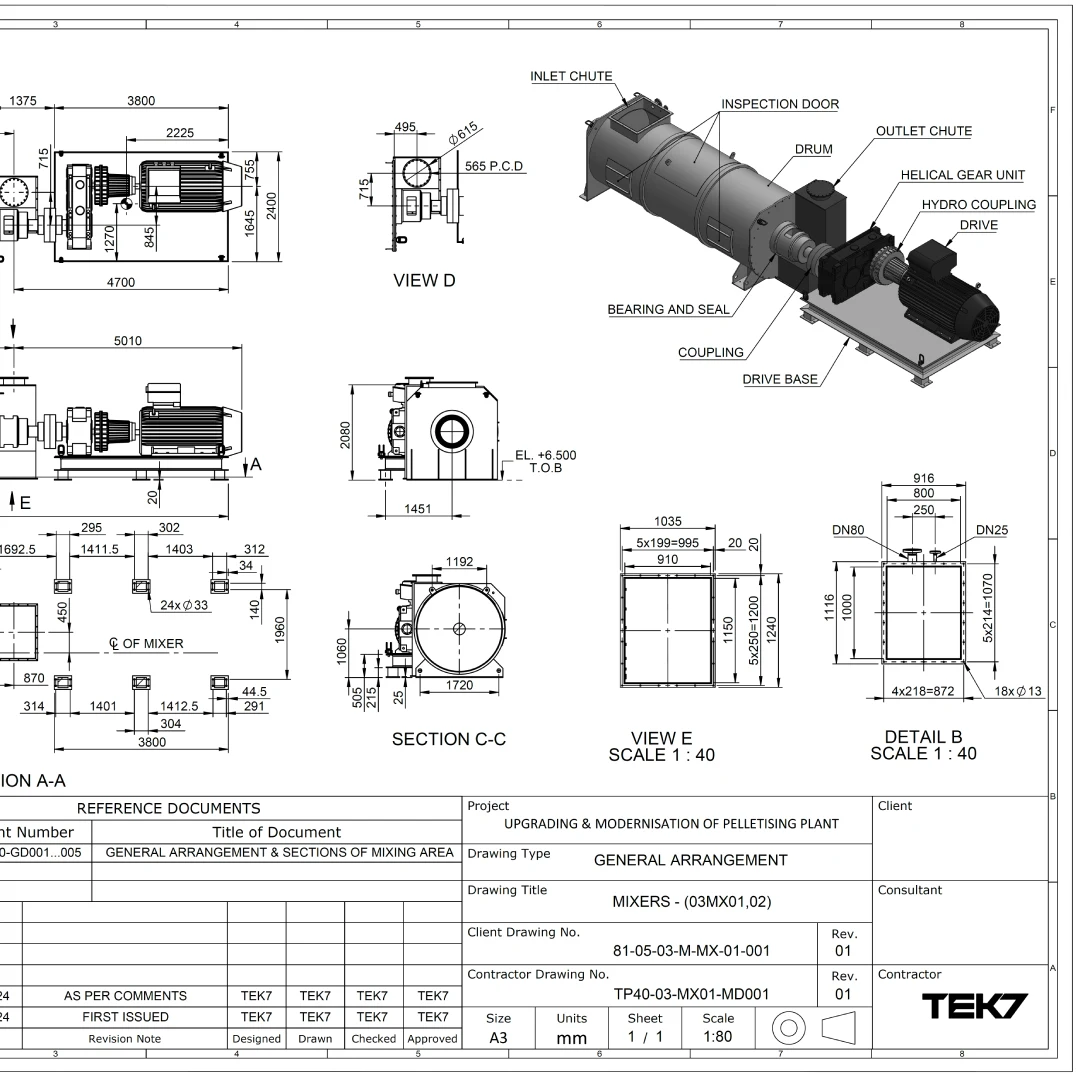

- Equipment Design and Integration; We design mechanical systems to enhance productivity, reliability, and maintainability. Our approach ensures seamless integration with other plant systems and adherence to quality and safety standards.

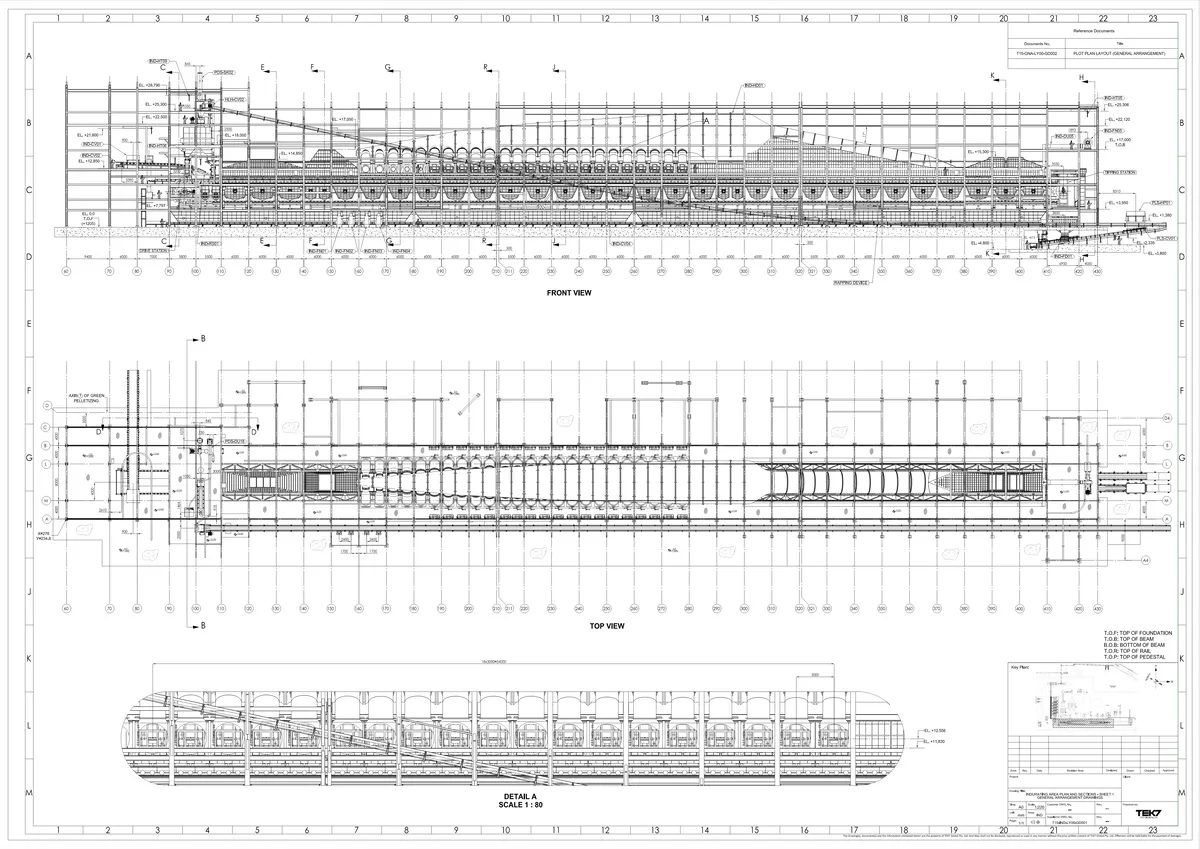

- Plant Layout and System Design; TEK7 develops optimised layouts to improve workflow, safety, and accessibility. This includes efficient design of material handling systems such as conveyors and storage facilities to maximisethroughput and operational flexibility.

- Maintenance Accessibility and Reliability; Designs incorporate features to enhance maintenance access and minimise downtime. We recommend predictive maintenance strategies and condition monitoring systems that proactively address equipment health and extend asset life.

Electrical Engineering

- Electrical Systems Assessment; We evaluate electrical systems to determine capacity, reliability, and safety requirements, identifying potential risks and performance limitations.

- Electrical System Design; We design electrical systems to meet operational demands with high reliability, efficiency, and resilience. Our approach optimises power distribution, incorporates redundancy where needed, and supports long-term energy efficiency.

Instrumentation and Control Engineering

- System Assessment; We evaluate instrumentation and control systems to determine performance, reliability, and integration requirements, identifying opportunities to enhance process monitoring and operational efficiency.

- Control System Design; We design and implement advanced control strategies and automation solutions to improve process stability, accuracy, and responsiveness. Our approach integrates data acquisition and modern control techniques to optimise operational performance and energy efficiency.

Civil and Structural Engineering

- Site Evaluation and Planning; We assess site layouts and structural conditions to determine suitability for new construction, expansions, or modifications, ensuring efficient integration with plant operations.

- Structural Assessment and Design; Our engineers develop structural designs for new or modified facilities, supporting safe and reliable installation of equipment and process systems while meeting all relevant codes and standards.

Piping and Utility Engineering

- Utility Analysis and Design; We assess utility requirements such as water, compressed air, steam, and cooling water, designing efficient distribution systems to reliably serve plant needs.

- Piping System Design; In collaboration with process engineers, we design piping networks optimised for flow, pressure, and temperature conditions, selecting materials based on corrosion resistance and process compatibility.

The final outcome of our engineering design work is a comprehensive, well-structured documentation package tailored to the specific project. These documents serve as critical reference points for procurement, construction, commissioning, and ongoing operations, ensuring clear communication, effective collaboration, and seamless knowledge transfer across all project stakeholders.

With TEK7’s multidisciplinary engineering expertise, the project, whether a new build or an existing plant enhancement, will be expertly planned and executed, delivering a safe, reliable, and high-performance pelletising facility ready to meet current requirements and future demands.