— TEK7

TEK7 Precision combustion for powerful results.

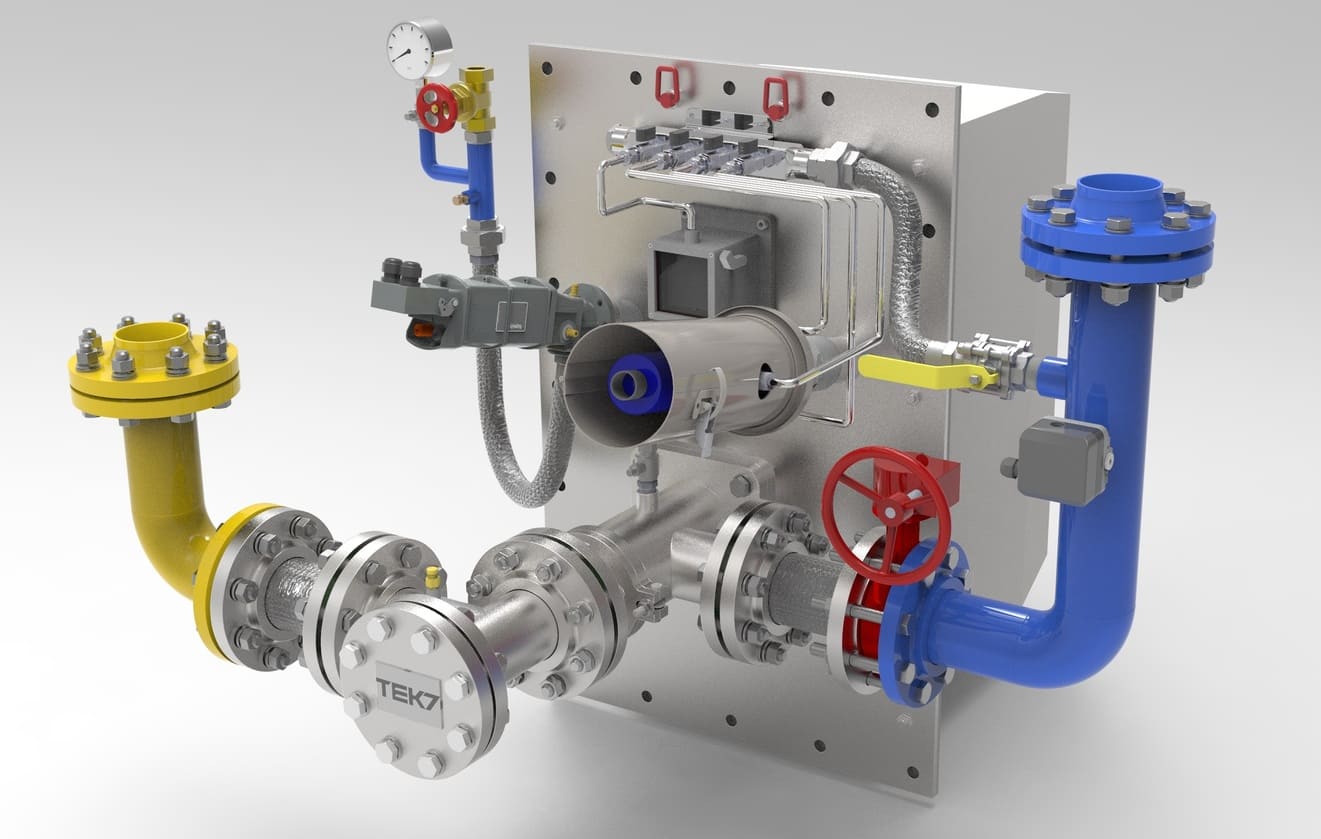

Custom Designed Burners

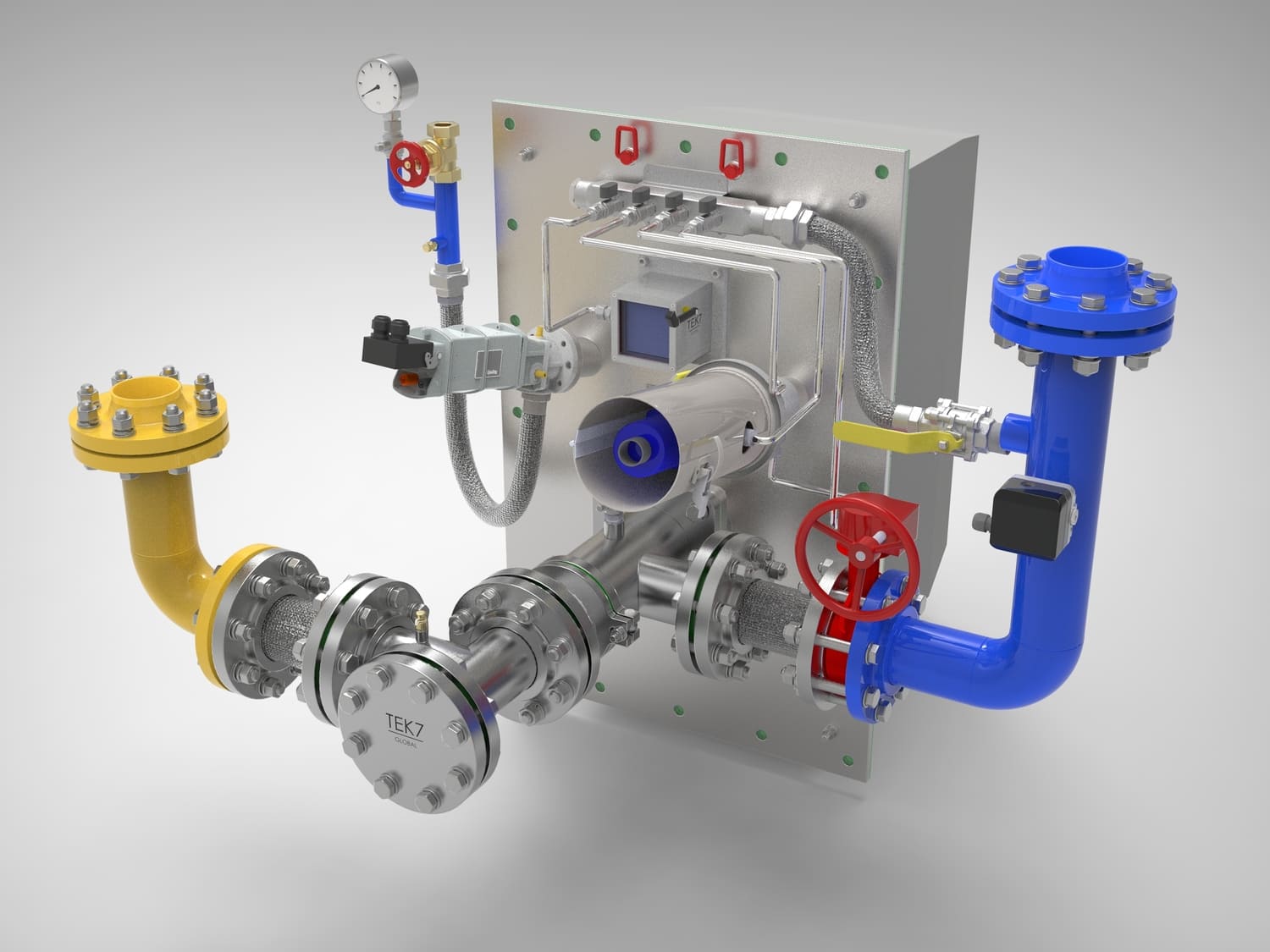

At the heart of efficient pelletising is a burner system that responds with accuracy, flexibility, and reliability. TEK7 approaches burner design as a critical enabler of process performance, not just a heat source. By combining plant-specific requirements with deep technical insight, we deliver custom designed burners that integrate seamlessly, adapt effortlessly, and perform consistently under the most demanding conditions.

TEK7 is globally recognised for its advanced burner systems engineered specifically for the demanding requirements of iron ore pelletising plants. As one of the industry’s most trusted suppliers, we have delivered high-performance burners to plants around the world, driving thermal efficiency, process stability, and environmental compliance.

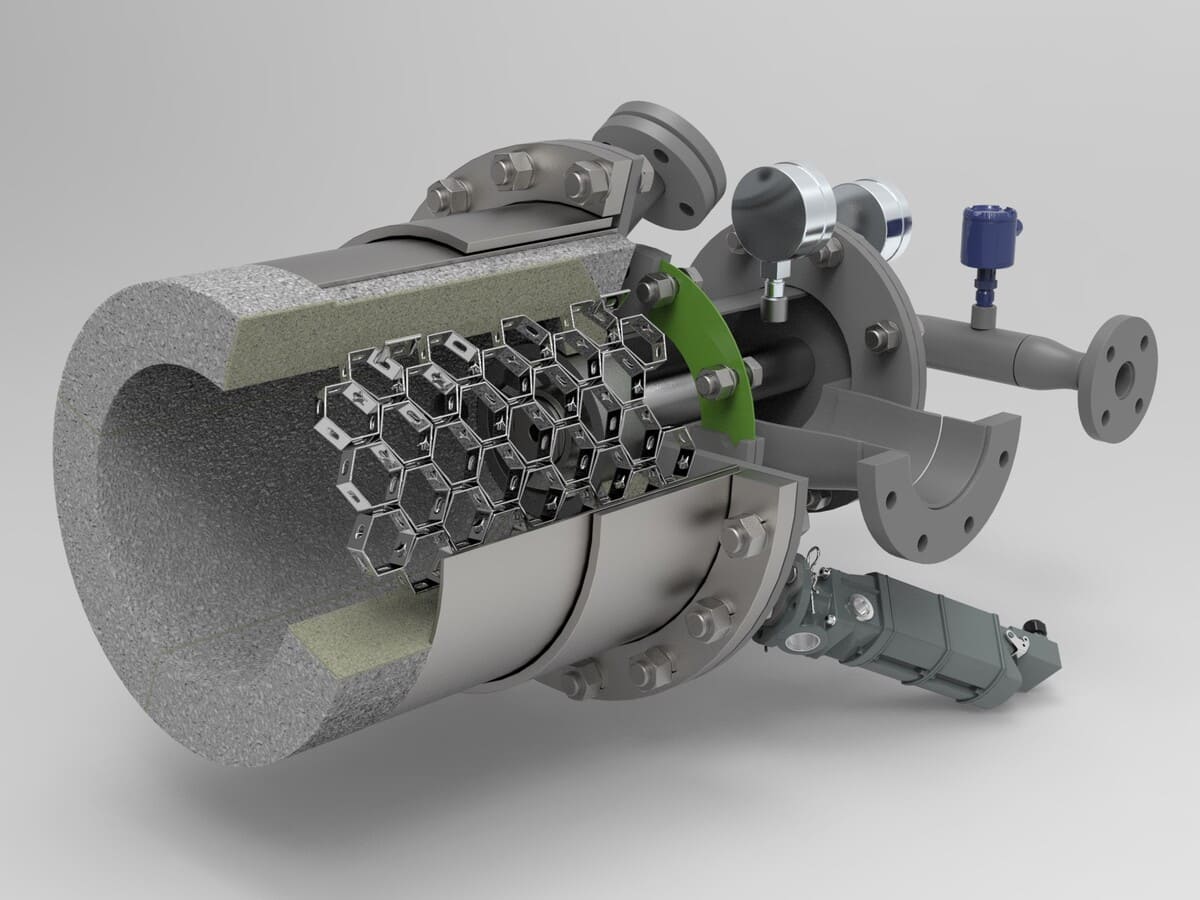

Our burner systems are the result of years of focused development, grounded in deep metallurgical process knowledge and real-world plant experience. Designed to meet the specific thermal profiles and load demands of induration furnaces, TEK7 burners offer superior fuel efficiency, precise flame control, and robust operation under varying process conditions.

A hallmark of TEK7’s burner design is its customization for compact combustion chambers, allowing seamless integration into existing furnaces without compromising refractory integrity. This feature is especially critical for brownfield upgrades, where spatial constraints and the preservation of refractory linings are vital considerations.

Flexibility is another cornerstone of our combustion technology. TEK7 burners can be configured to operate on a wide range of fuels, including various natural gases, syngas, and liquid fuels such as light and heavy oils. This multi-fuel capability allows clients to adapt to changing fuel availability and cost scenarios without the need for extensive equipment changes.

Our burners are also engineered to offer exceptional turndown ratios—up to 1:50—providing precise temperature control across a wide operating range. This high turndown capability ensures smoother operation during low-load conditions, facilitates energy savings, and enhances furnace responsiveness during process transitions.

Whether for greenfield installations or brownfield retrofits, we tailor each solution to match the plant’s capacity, fuel mix, and emission targets, ensuring optimal heat transfer, minimised fuel consumption, and reduced NOₓ and CO emissions.

From design and fabrication to installation, tuning, and commissioning, TEK7 provides end-to-end combustion engineering with a proven track record in enhancing induration zone performance, extending refractory life, and enabling smoother startup and shutdown procedures.