TEK7 Precision in the lab, performance in the plant.

Laboratory Testing & Pot Grate Test

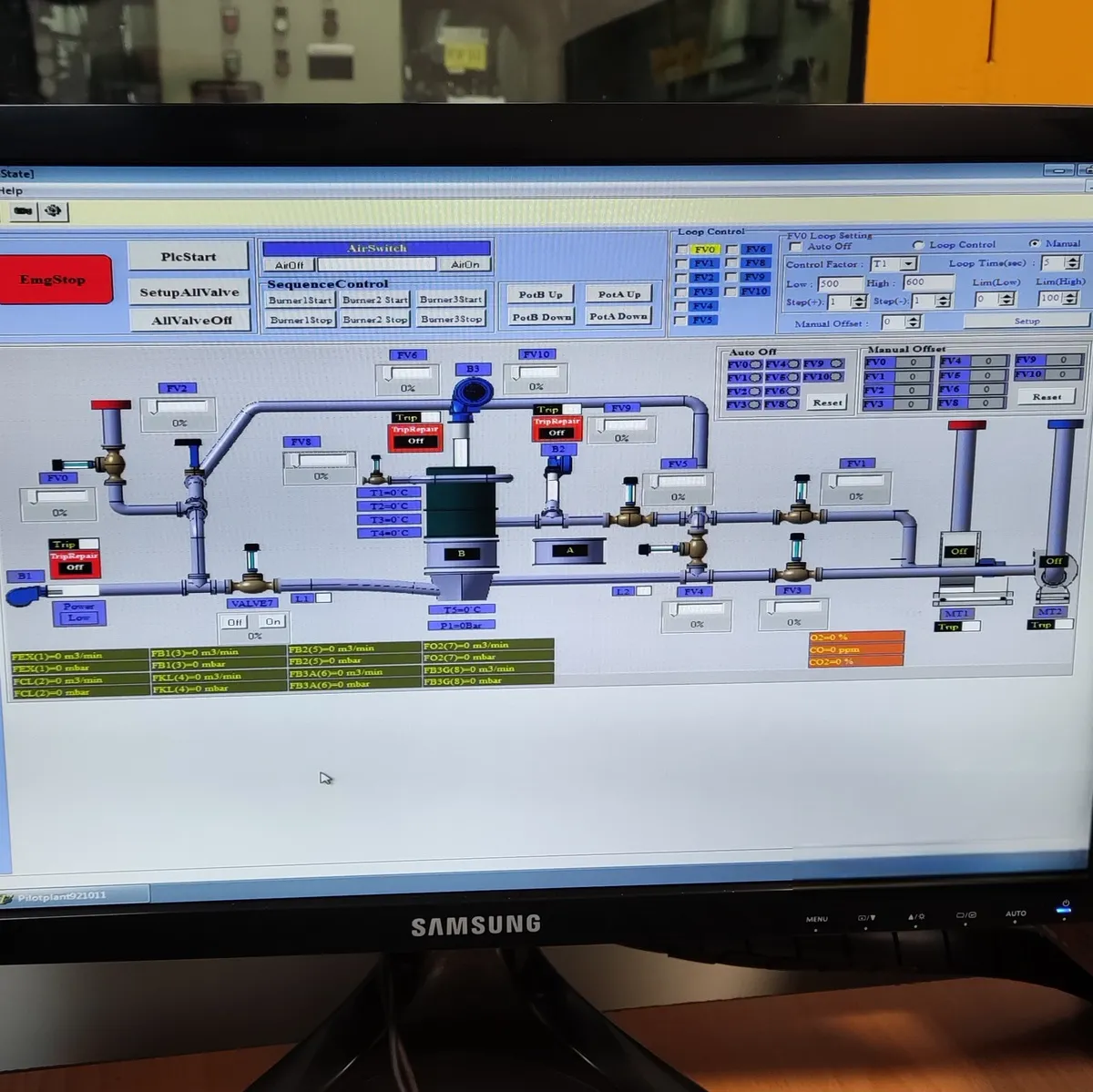

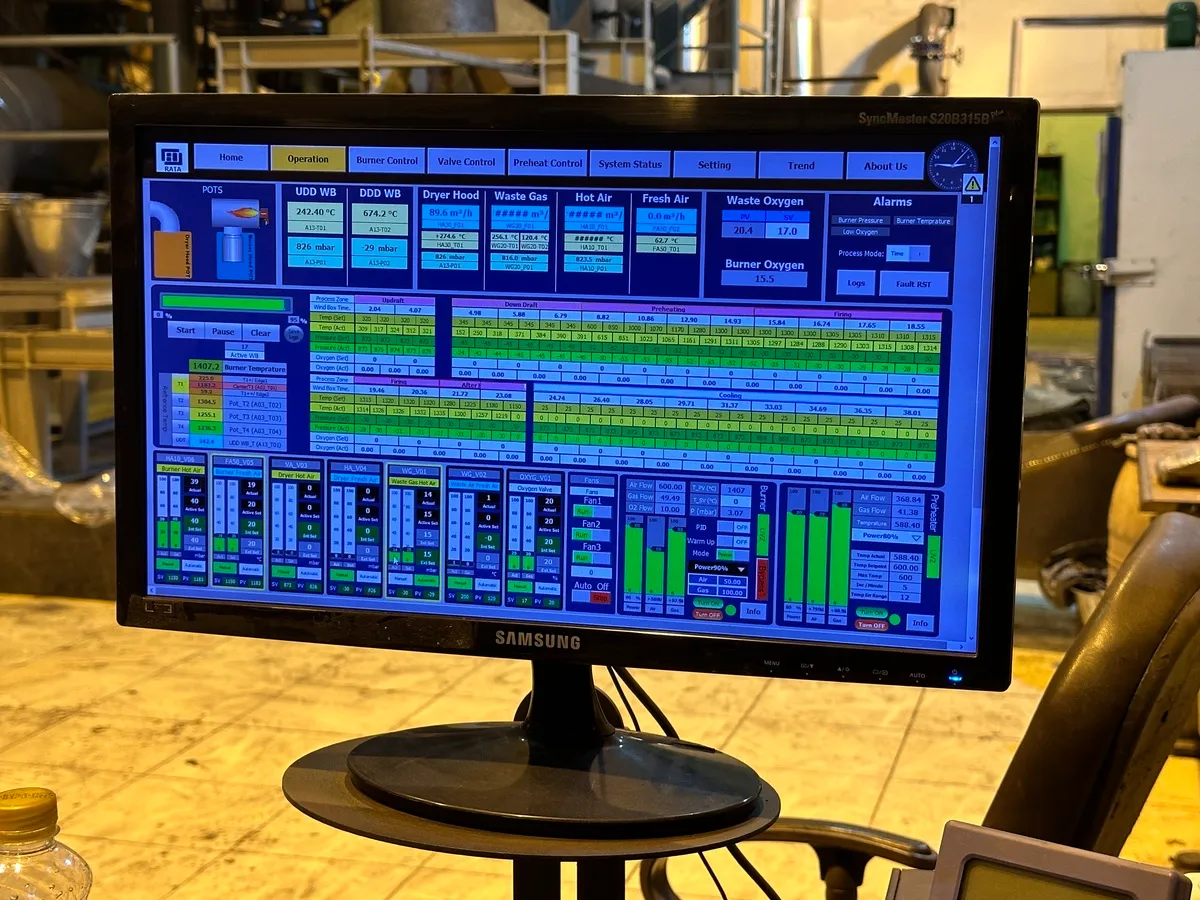

At TEK7, laboratory testing especially the Pot Grate Test is a crucial step in understanding and optimising pellet quality. By replicating the pelletising process under controlled conditions, we generate reliable data that drives smarter engineering decisions and ensures consistent high-quality output. Our tailored testing approach helps fine-tune operations, verify product performance, and troubleshoot process challenges, delivering results you can trust for every project.

— TEK7

Laboratory testing provides valuable insights into the structural and metallurgical characteristics of iron ore pellets produced under different process configurations. These tests inform process design, quality control and operational improvements, supporting projects at every stage from initial design to long-term optimisation.

For each project, TEK7 designs a tailored set of Pot Grate Tests to simulate the full pelletising process under laboratory conditions. The results provide critical data to guide engineering decisions, verify product performance and ensure that plants, whether newly built, upgraded or optimised, deliver consistent, high-quality pellet output.

Key Benefits

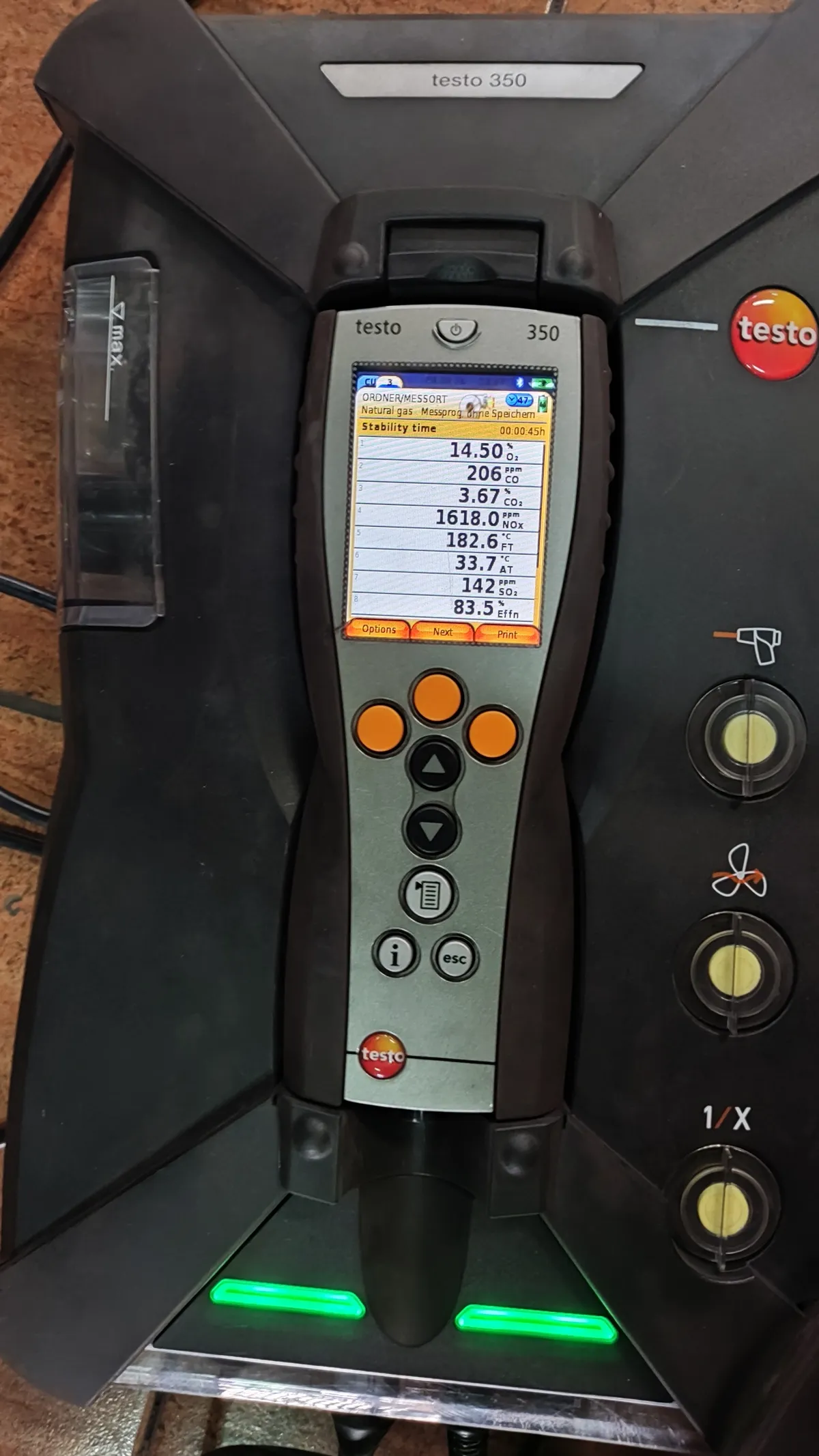

- Process Optimisation; Pot grate testing enables the fine-tuning of operational parameters such as green pellet moisture content, firing temperature, and residence time to achieve optimal pellet quality, reduce energy consumption, and increase process efficiency.

- Quality Assurance; Tests confirm that the iron ore pellets meet required industry standards and client specifications, supporting long-term quality control and market competitiveness.

- Product Performance Evaluation; Pellets are assessed for their physical and reduction properties, including size distribution, compressive strength, and metallurgical behaviour. These insights are critical for ensuring durability during transportation and consistent performance in ironmaking.

- Process Troubleshooting; Testing helps identify bottlenecks or deficiencies in the current or proposed process setups. By isolating issues, targeted improvements can be made to minimise production losses and improve reliability.

Test Parameters

- Green Pellet Properties

- Compression Strength

- Drop Number

- Shock Temperature Resistance

- Bulk Density

- Fired Pellet Properties

- Compression Strength

- Tumble Strength and Abrasion Index

- Reduction Behaviour:

- Sticking Index

- Disintegration Index

- Metallisation Index

TEK7 manages the entire laboratory testing process in-house, from test design and preparation through to execution, supervision, and analysis. Our team of experienced process engineers ensures that each Pot Grate Test is tailored to the specific project requirements, whether for a new greenfield development or the upgrade and optimisation of an brownfield plant. All testing is carried out using TEK7’s own protocols, equipment, and technical resources to maintain consistency, accuracy, and traceability.

By keeping full control of the testing workflow, TEK7 guarantees high-quality data generation, faster turnaround times, and actionable results that directly support engineering decisions and process optimisation.