— TEK7

TEK7 Optimised for efficiency. Built for endurance.

Optimised Pallet Cars

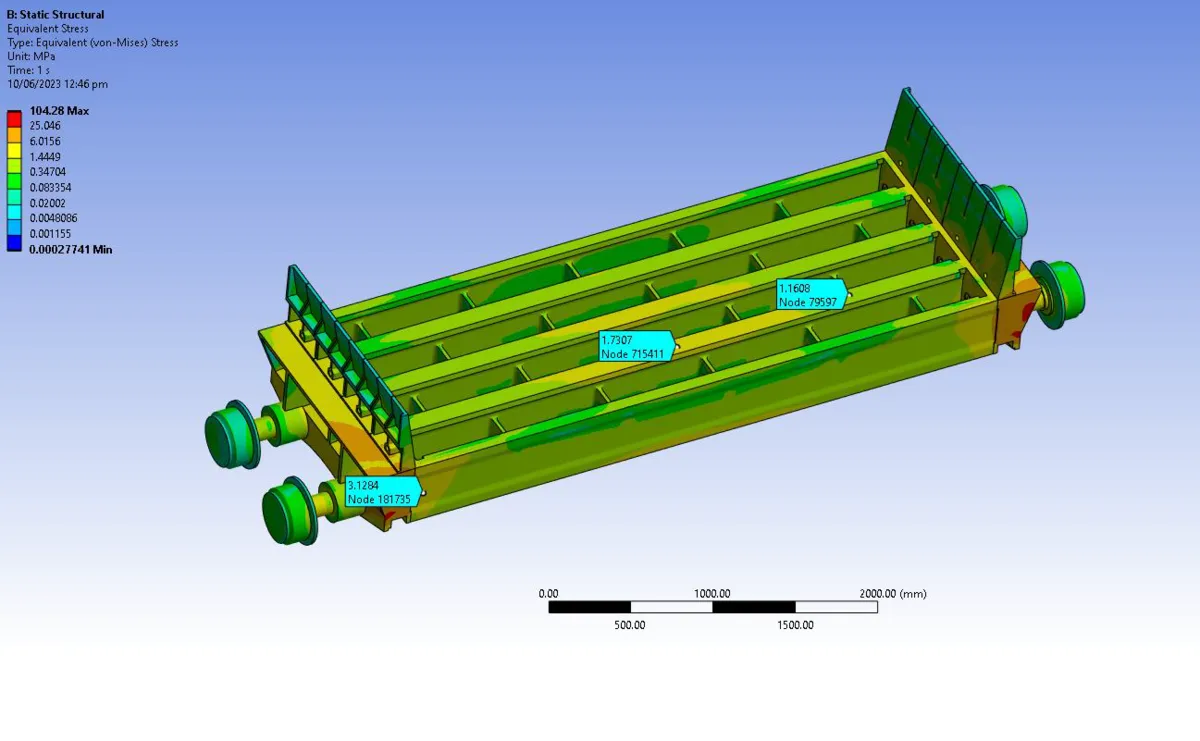

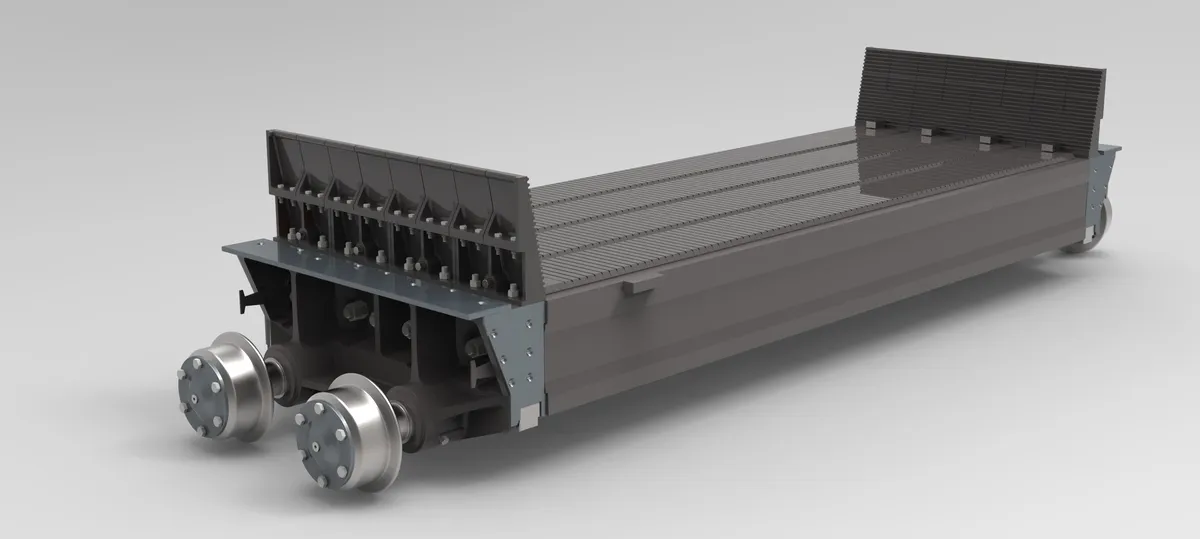

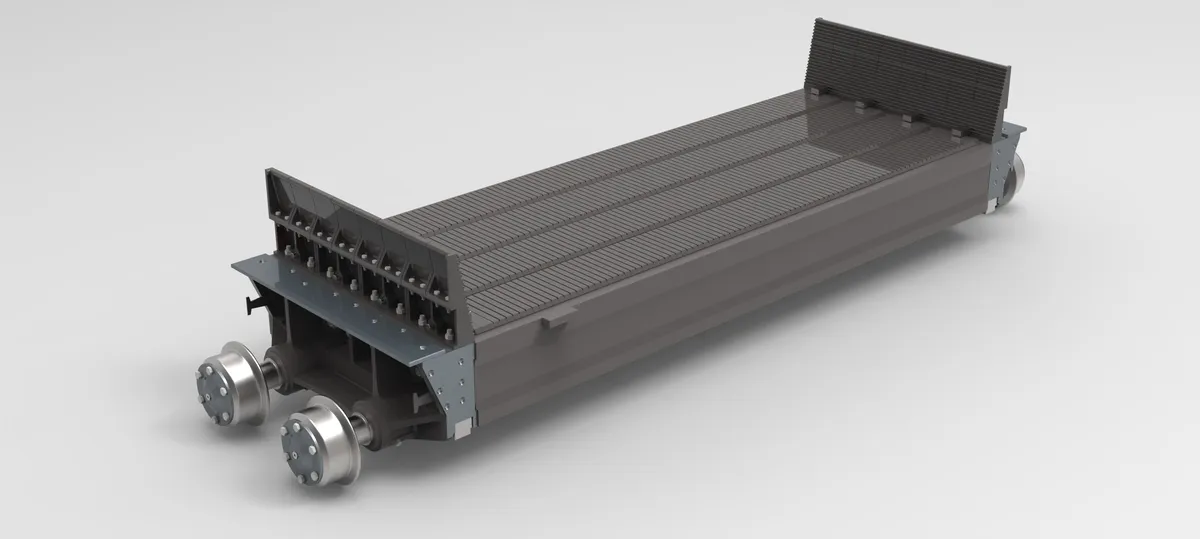

In high-temperature, high-demand pelletising environments, the pallet car is a critical link in achieving reliable and efficient production. TEK7 designs and delivers next-generation pallet car solutions built for superior durability, thermal performance, and operational reliability. Whether applied in system upgrades or new installations, our designs minimise heat loss, reduce wear, and enable consistent, high-quality output with reduced downtime and maintenance effort.

TEK7’s advanced pallet cars are engineered to withstand extreme thermal loads, abrasive materials, and repeated mechanical stresses. Using optimised lightweight structures, advanced materials, and precision manufacturing techniques, we deliver systems that provide longer service life and improved process stability under demanding production conditions.

Each pallet car design is tailored for optimal performance across the induration process. Innovative sealing systems and precision-fit components reduce heat leakage and material spillage, ensuring efficient energy use and stable temperature profiles. Maintenance accessibility is prioritised, allowing easier inspections, faster part replacements, and extended operational uptime.

By enhancing reliability and thermal consistency, TEK7’s pallet car solutions directly improve plant availability and pellet quality. Drawing on global experience in pelletising plant optimisation, we ensure every solution supports the client’s current production targets while remaining adaptable to future capacity and performance requirements.